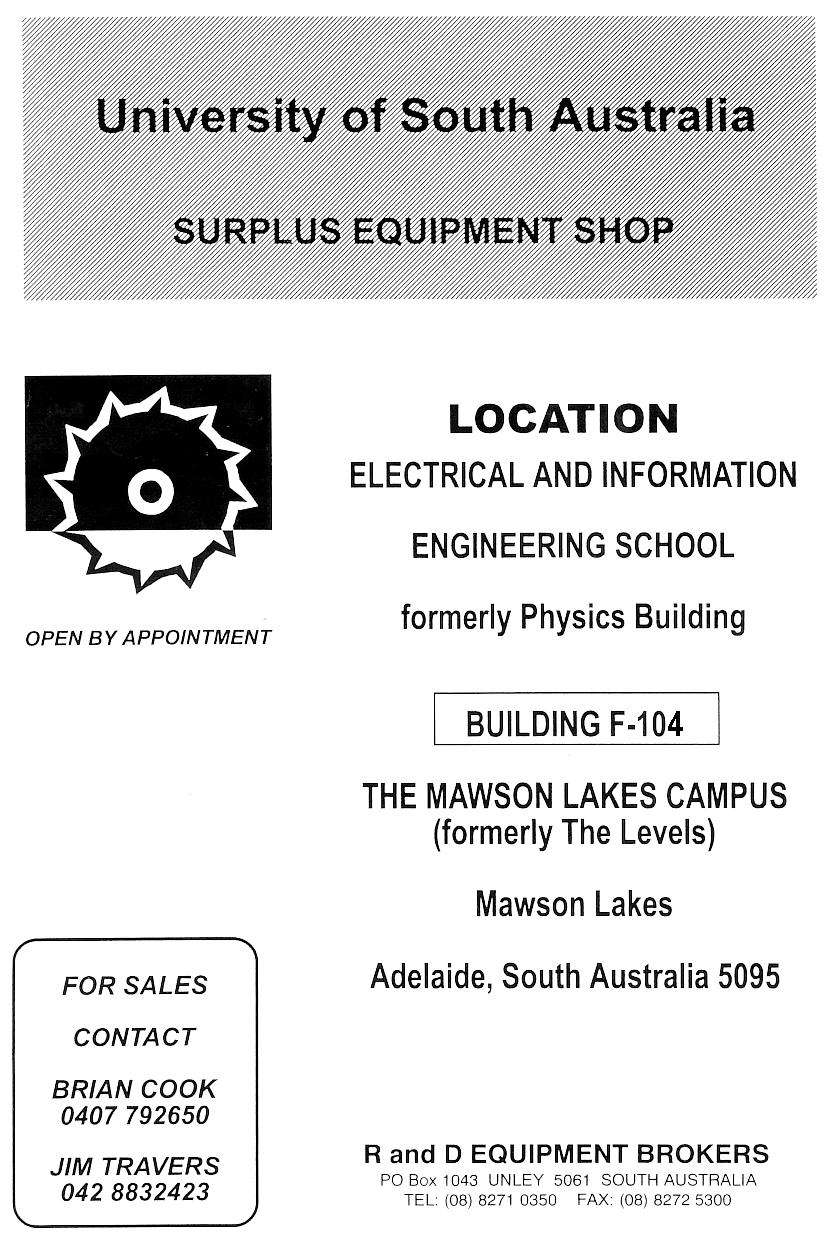

EB Mawson Lakes Campus

click for larger image

EB Mawson Lakes Campus |

click for larger image |

INDEX

EH General

EHA eng ineering

EHB EMC

EHC SCT

EHD High Power Transmission CAMR SEC

|

|

|

|

|

|

|

|

|

|

|

ION Implanter accelerator

and magnet seperator

EHC-417

Ion Implanter description

Ions of the doping material are produced when atoms of the dopant are

fed into the ion source and undergo collisions with electrons.

Supply positive 0-10kv.

1. Electrons emitted from cathode of the source.

2. resulting collisions cause electrical discharge producing positively

charged ions.

3. with negative voltage of 0-30v they are extracted from the source

by the extraction lens forming a focussed ion beam.

4. Initially focussed ions accelerate in a column to energies up to

200KeV at terminal potential.

5. Through velocity a portion of secondary electrons can part from

ions or be produced through collisions with stray gas molecules.

6. Electrons cannot return to the source. A secondary electron suppressor

is used.

7. Accelerated beam of ions enters electrostatic lens to set up an

electric quadrupole field focussing ions towards the beam tube axis.

8. To obtain required ion species magnetic field strength is altered

to deflect ions of different masses through different angles.

9. The final beam passes through a second quadrople focus lens for

final beam diameter adjustment to implant the wafer.

10. To deflect plate sets electrostatically scan the beam over the

wafer.

11. First set for vertical deflection Y, second set for horizontal

deflection X, deflection X-Y and hybrid.

12. Vertical scanner most neutral particles generate in scanning.

13. Horizontal scanner (neutral trap) 7 degree bend trapping unreflected

neutral atoms.

14. Target chamber entered by beam through matrix (variable for different

diameter wafers)

15. Faraday strips measure the oversized beam to ensure whole target

area is implanted.

16. Electron suppressor reflects back scattered electrons at wafer

surface back to wafer guaranteeing exact measuring of the implanted dose

by measuring only the ion current.

17. Wafers located on 2 carrousels holding 20x3inch (75mm) wafers per

deck.

18. 2 inch (50mm) wafers can be used.

Further details are available relating to each step and function as extensive detailed information has been prepared during the operations for use as a research tool.

(EHC-417 = items B-L)

click pictures

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

|

|

|

|